Anodising

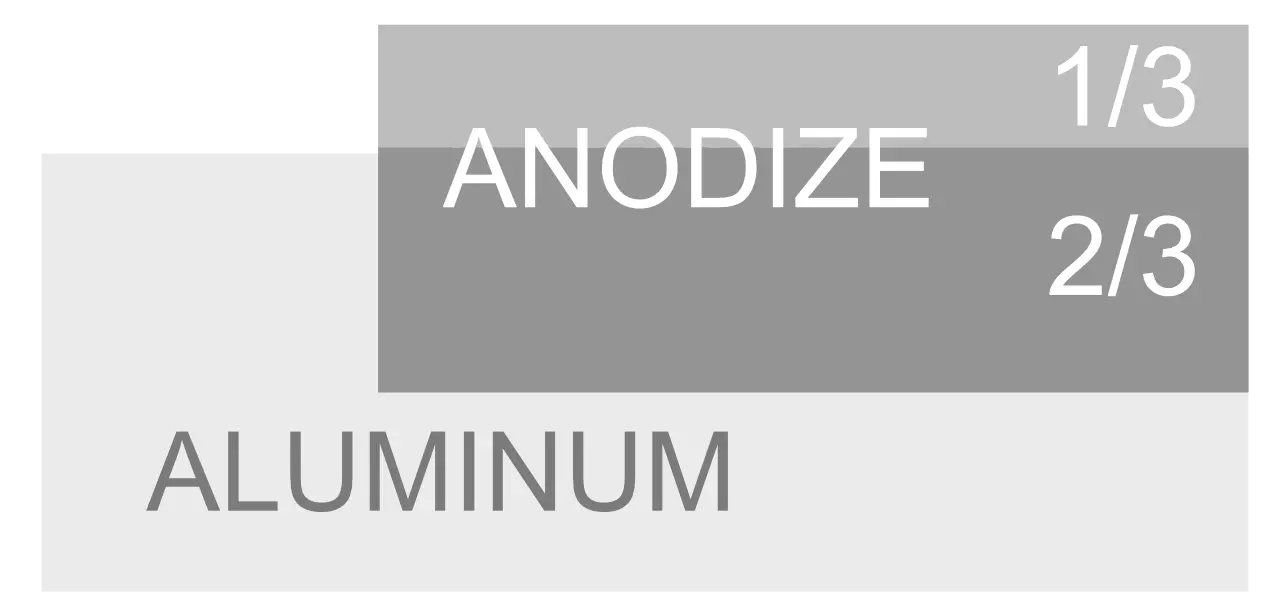

Unlike galvanic processes, electrolytic oxidation (anodising) of aluminium does not deposit a metallic layer on the base material. In this process, the top layer of aluminium is converted into an oxide (Al203). The oxide layer grows 2/3 into the base material and 1/3 onto the base material. The growth is also highly dependent on the structure and alloy of the aluminium. However, this not only influences the growth of the oxide layer, but also its optical appearance, colouring capacity, hardness and corrosion resistance. It is therefore essential to select the base material carefully.

Electrolytically oxidised aluminium

The resulting anodised layer is current-insulating and corrosion-resistant. The achievable layer thicknesses are only 5-10µm for copper-containing aluminium alloys with a copper content greater than 2%, and up to 25 µm for copper-free alloys. This process is used in many areas of industry. Anodised coatings are very variable and can be used decoratively. By specific mechanical pre-treatment or by partial covering of surfaces and drill holes, complicated requirements as well as optical effects such as glossy to silky-glossy or matt surfaces can be achieved. The good adsorption capacity of the porous anodised layer enables safe and permanent colouring. The anodised pores are closed and the dyes are sealed into the layer by subsequent sealing.

Anodising aluminium

Properties

Achievable layer thicknesses: With copper-free aluminium up to max. 25 µm and with aluminium alloys with more than 2% copper (turning and milling quality) only 5-10 µm are possible. The coatings produced with high copper alloys are softer and not as durable. Only 1/3 of the generated layer thickness is noticeable as a "deposit". 2/3 of the layer diffuses into the base material. Please take this into account for fitting parts! Due to our close cooperation with various suppliers, we can offer you glass bead blasting, grinding and polishing as pre-treatment.

Protective layer

Summary

The anodising process is a method of surface finishing to create an oxidic protective layer on aluminium by anodic oxidation. The properties of the aluminium surface are changed in the process.

- Our baths allow us to process workpieces with dimensions up to 105 x 295 cm in natural, grey, black, red, gold, orange, brown and blue.

- Optical (colour and surface structure) as well as haptic properties can be taken into account according to your wishes and requirements.

Protection & Haptics

Advantages

- Improvement of corrosion protection, optical properties and surface hardness through anodising.

- Complicated requirements can be realised, for example, by partially covering bores and threads.

- Dimensional accuracy of your workpiece.

It should be noted that only 1/3 of the generated layer thickness is noticeable as "application". 2/3 of the layer diffuses into the base material. Please note this for fitting parts!

Anodising colours

During colour anodising, the outer layer of the aluminium surface is opened and oxidised in an electrolytic bath. This forms a porous layer that enables the absorption of colourants. The oxide layer is then filled with dyes, creating the desired colour on the surface. After colouring, the layer is sealed to protect the colour and increase durability.

Colour Oxal

Summary

Colour anodising is an advanced technique that not only protects aluminium surfaces, but also gives them a variety of colours and improved properties.

- Our baths allow us to process workpieces with dimensions up to 105 x 295 cm in natural, grey, black, red, gold, orange, brown and blue.

- ten other colours up to a size of 100 x 60 cm.

Yes We Do

Advantages

- Enables a wide range of colours and shades.

- Colour does not flake or peel, thus increasing durability.

- The process produces only small amounts of waste and uses no harmful chemicals, making it environmentally friendly.

- Suitable for a wide range of applications.

High-tech made in Germany

We have been audited and certified in quality management and environmental management since 2008. The highest standards are a matter of course for us and are reflected in great acceptance and customer satisfaction.

We keep emissions low through modern filter systems and save resources through energy recovery.

A photovoltaic system generates electricity for our own use and is designed for expansion. Other measures such as waste avoidance and proper disposal are a matter of course for us.